Projects/Publications

Composite Power Insulator Projects

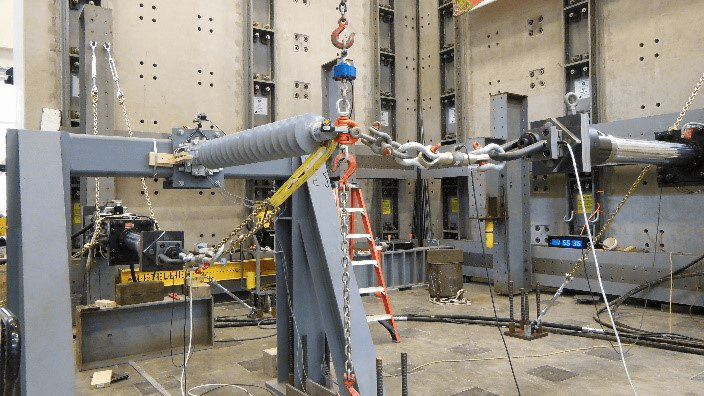

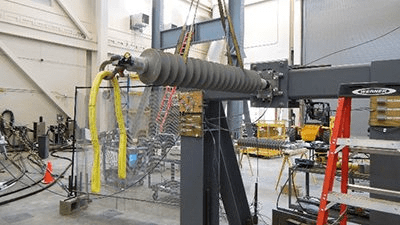

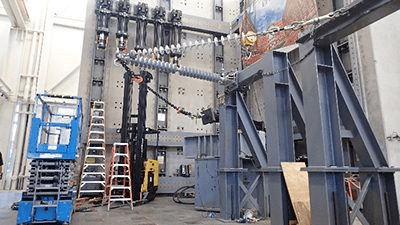

This project tested three different types of composite insulators for the high voltage power transmission lines. Three directional loads are applied on the tip of the insulator (three different loading points in the case of the diamond type insulator for T-pylon). The laser reflector target was mounted at the tip of the insulator for measuring the three-dimensional coordinates during the test in real-time. Four strain gauges were installed on the strategic locations of the composite insulator core.

Single post insulator

Braced post insulator

Diamond type insulator for T-pylon

Inspection of Wood Distribution Poles

With approximately 130,000,000 timber distribution poles in North America, treated wood has been called “the backbone of the nation’s electrical distribution system.” Timber poles are susceptible to decay and section loss due to insects, fungi, and rot. Linemen servicing electrical components must quickly assess the structural safety of the pole. However, the decay and section loss most frequently occurs 6 to 18 inches below the ground line, where it is not readily detected. This research effort, funded by the Duke Energy Corporation, will investigate promising techniques for use by linemen to assess pole health, thereby improving safety and reducing costs.

- Erica Barber (2016) “Experimental Evaluation of Low-Cost, Portable, and Rapid Nondestructive Evaluation Methods for Timber Distribution Poles,” Master of Science Thesis, University of North Carolina at Charlotte, Department of Civil and Environmental Engineering. 146p.

NC DOT STEEL SHEET PILE PROJECT

Civil Engineering researchers in UNC Charlotte’s Lee College of Engineering are working on a North Carolina Department of Transportation project to determine the axial bearing capacity of steel sheet piles used in short span bridges.

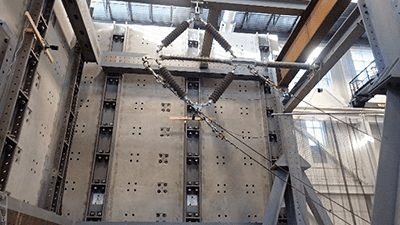

Using the geotechnical pit in the high bay laboratory of the Energy Production and Infrastructure building, the research team has installed sheet piles instrumented with strain gages, strain transducers, and accelerometers to monitor the behavior of the piles during driving and for axial compression load testing.

During the summer of 2014, the team backfilled the geotechnical pit with compacted silty sand, carried out several in-situ tests to characterize the compacted soil, and measured relevant geotechnical properties. The in-situ tests included SPT, CPT, MASW, and Cross-hole seismic testing.

After backfilling the pit, the team installed two rows of PZ-27 steel sheet piles. The installation required an impact pile driving hammer, as well as a vibratory hammer. The first row was installed on July 29th and the second row was completed on August 19th.

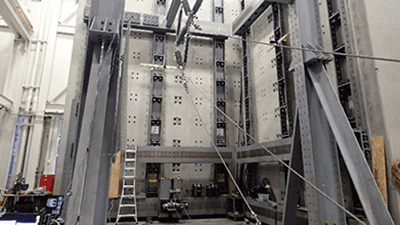

The team has now constructed a load frame above the installed sheet piles to do the dynamic and static loading test with a 220 kips hydraulic actuator. The load frame, or Geotech Portal, is designed for the 300 kips total vertical load.

This ongoing project has benefited from technical and material support from several companies including (in alphabetical order): GRL of Charlotte, Hayward Baker, ICE of Matthews, Lee Carolinas, S&ME of Charlotte, and Skyline Steel. Their support and assistance is greatly appreciated and acknowledged by the research team.

- Rice, C.D., Pando, M.A., Whelan, M.J., Ogunro, V.O. (2014). “Vertical load capacity of steel sheet piles for bridge abutments- preliminary assessment for sand conditions.” 9th International Conference on Short and Medium Span Bridges, Calgary, Canada, (436)1-10.

- Sylvain, M.B., Pando, M.A., Whelan, M.J., Ogunro, V.O., Park, Y., Koch, T. (2015). “Large scale laboratory testing to evaluate the axial load capacity of sheet piles for bridge abutments.” 15th Pan-American Conference on Soil Mechanics and Geotechnical Engineering, Buenos Aries, South America, 290-297.